Application area in chemical and oil and gas industry it is necessary to heat pipelines of several kilometers long. Due to the fact that maximum permissible connection lenght of one heating section is about 200 meters, heating of long pipelines by standart heating cable is limited.

Advantages Heatline-SKIN

- Efficiency. SKIN-counductor function as heating element and feed line at the same time. There is no need in costly accompanying power-supply system. System "Heatline-SKIN" enable to heat parts of pipeline up to 30b km long with power supply at one end.

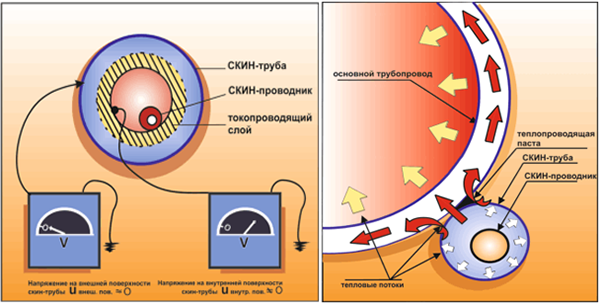

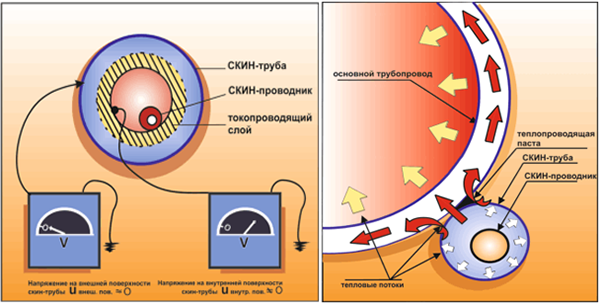

- Electrical safety. Outer surface of SKIN-pipe is grounded and has zero potential relative to ground.

- Long service life-not less than 25 years. Majority of heat (up to 80%) passes in SKIN-pipe, besided SKIN-conductor practically doesn´t heat. SKIN-pipe is lasting, so long as it is situated under lag and provective cover of pipeline.

- Repairability. Presence of enough broaching boxes simplifies access to SKIN-conductor without damage of heat-insulation.

- Reliability. Solid heat-segregating elements in the form of steel pipes provide mechanical strength and protection of current-carrying conductors from damages. This system showed itself to good advantage thanks to 30-year service life.

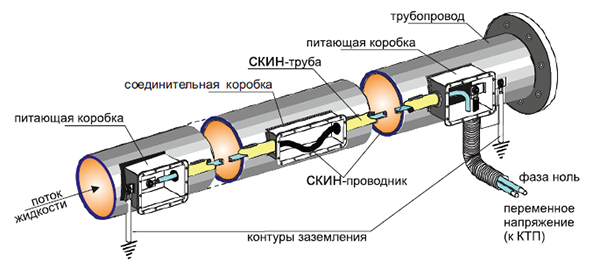

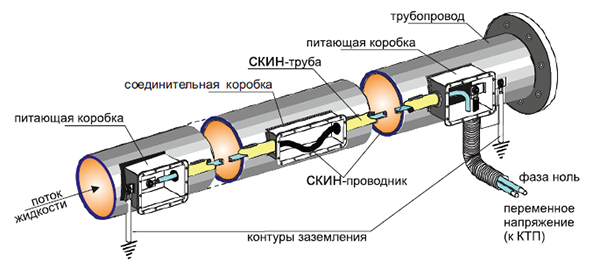

Composition Heatline-SKIN

- SKIN-conductor represents copper conductor of special construction. Outside the conductor there is a special two-layer insulation which endures nigh voltage and mechanical load. Cutset of SKIN-conductor is 6-40 mm.

- SKIN-pipe represents drawn pipe, whice is manufactured from special carbon steel with set ferromagnetic settings. Diameter of SKIN-pipe is 16 - 60 mm, wall thickness is 2,5-4 mm.

- Accessories: connectors for SKIN-pipe, connecting boxes,feed devices and terminations, equipment for installation of system elements on line bends and stop valve, heat-conducting paste.

- Power source of system Heatline-SKIN is a complex transforming station, which involves distributive cell of nigh and low ways, special feeding transformer.

- Сontrol system is intended for formation of switch and cutoff signals,date control of heating system. Date control is realized from air temperature sensor and heating pipeline throung the special controller. Control system minimizes current consumption from environment temperature. It is provided the possibilitty of removal of system working settings and their transmission on dispatcher desk if it is necessary.

Principle of operation Heatline-SKIN

Skin-pipe is installed on pipeline so as to provide reliable heat contact with principal pipeline. SKIN-conductor is placed into ferromagnetic steel SKIN-pipe. On the distal end SKIN-conductor connects wich SKIN-pipe in a short circuit. SKIN-pipe is grounded on both ends. On the near end voltage of commercial frequency is imposed between SKIN-conductor and SKIN-pipe. The currents of reversed direction flow near SKIN-conductor and SKIN-pipe,and in the SKIN-pipe the current flows near inner layer of pipe which is about 1 mm thick at that. Also potential of outer surface of SKIN-pipe remainz zero. Due to magnetic characteristics of SKIN-pipe there is SKIN-effect which leads to greater visibility of pipe resistance than on the direct current. Due to small thickness of SKIN-layer principal heat emission occurs in steel pipe. At right installation of SKIN-system 60-80% of heat is evolved in SKIN-pipe and only 20-40% in SKIN-conductor is transferred to heated pipeline. Fixation of SKIN-pipe to principal pipe is carried out wich the help of steel hoops and special tool or spot welding.

Technical characteristics Heatline-SKIN

| Parameter |

Unit |

Value |

| Sypply voltage |

V |

up to 3500 |

| Frequency |

Hz |

50 |

| Working range of temperatures |

ºС |

+5...+180 |

| Linear power |

W/P |

up to 100 |

Certification

Certification of conformance to other national standarts is possible on reqest.

Projection

The project involves heat engineerring calculation, project feasibility study, explanatory report, projection and design documentation, specification of materials and equipment and also all necessary instructions and descriptions. For making out an application for calculator of heating system of industrial pipeline we offer you to fill in a questionnaire.

Installtion

The Production company Heatline realizez a full installation or contract supervision of system Heatline-SKIN.